Traditionally, crafting foam parts often involved the complexity and cost associated with CNC machines. However, Neckog Industries, a cutting-edge technology company, has shattered the mold with its groundbreaking Flovv-e technology. This remarkable device offers manufacturers unprecedented precision, efficiency, and cost-effectiveness in the production of foam parts. But Neckog Industries’ innovation doesn’t stop at the Flovv-e itself; it extends to their proprietary mold release, a secret ingredient that enhances the entire process.

In this article, we delve into how the Flovv-e and Neckog Industries proprietary mold release combine to reshape the manufacturing landscape.

Challenges of Traditional Manufacturing

Historically, crafting foam parts required reliance on CNC (Computer Numerical Control) machines, which brought with them a set of challenges:

High Costs: CNC machines come with a significant initial investment, limiting access to smaller businesses and startups.

Complex Programming: CNC machines demand skilled programmers and time-consuming setup, contributing to longer production lead times.

Material Waste: The nature of CNC machining often led to material wastage, increasing both costs and environmental concerns.

Limited Versatility: CNC machines are designed for specific tasks, limiting their adaptability to diverse foam part manufacturing needs.

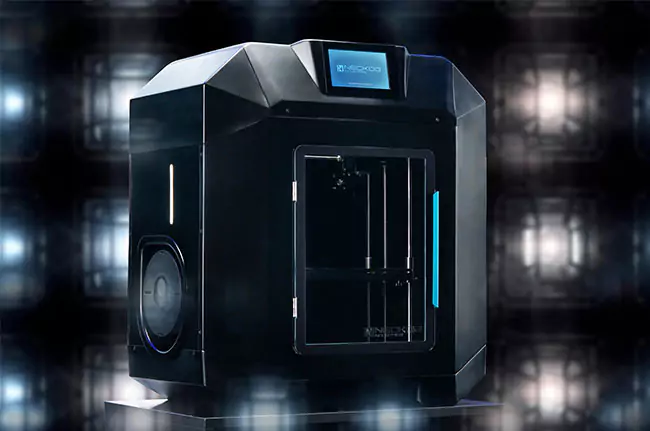

The Flovv-e Game-Changer

Flovv-e represents a paradigm shift in the production of foam parts. It offers an efficient and cost-effective solution for manufacturers, eliminating many of the limitations associated with traditional CNC machining.

-

- Cost-Efficiency: Flovv-e significantly reduces upfront costs compared to traditional CNC machines, making it accessible to a broader range of businesses.

- Simplified Operation: Flovv-e is designed with user-friendliness in mind, minimizing setup time and accelerating production by eliminating the need for a team of skilled programmers.

- Minimal Material Waste: The Flovv-e minimizes material wastage, benefitting both cost and environmental sustainability through its automated precision cutting and shaping.

- Unmatched Versatility: Flovv-e’s adaptability allows it to produce a wide variety of foam parts, from intricate designs to large-scale production runs, accommodating various foam materials and densities.

The Power of Proprietary Mold Release

Neckog Industries’ proprietary mold release is a well-kept secret that enhances the production of foam parts. This specialized compound is engineered to reduce friction and adhesion, ensuring a smooth and efficient release of foam parts from molds.

-

- Enhanced Efficiency: The proprietary mold release reduces friction and adhesion, guaranteeing a smooth release of foam parts from molds, saving time and minimizing the risk of defects.

- Improved Surface Finish: By reducing the risk of adhesion and mold damage, the proprietary release ensures that foam parts emerge with impeccable surface finishes, eliminating the need for additional finishing steps.

- Cost Reduction: Enhanced efficiency means less downtime and reduced maintenance costs for molds. The proprietary mold release not only improves quality but also lowers production expenses.

The Fusion of Flovv-e and Proprietary Mold Release

When Flovv-e’s state-of-the-art technology is combined with Neckog Industries’ proprietary mold release, the result is a manufacturing powerhouse.

-

- Unparalleled Precision: Flovv-e’s precision combined with the mold release’s efficiency ensures that each foam part is manufactured with consistent accuracy, with minimal risk of imperfections.

- Efficiency and Cost-Efficiency: The proprietary mold release’s contribution to efficient mold release is a perfect match for Flovv-e’s automation, reducing labor costs and material wastage.

- Versatility: The combination accommodates various foam materials and densities, making it versatile for manufacturers across industries, from aerospace to healthcare.

Applications and Advantages

The Flovv-e and proprietary mold release are set to revolutionize foam part manufacturing across industries, offering applications and advantages that are vast and diverse:

-

- Aerospace: The partnership enhances fuel efficiency and performance through lightweight, durable foam components.

-

- Automotive: Foam parts with enhanced surface finishes contribute to better safety, comfort, and fuel efficiency.

-

- Construction: Foam insulation with a perfect surface finish improves energy efficiency in buildings.

-

- Healthcare: Foam components for prosthetics and orthopedic devices emerge with quality that exceeds industry standards.

Conclusion

The fusion of Flovv-e with Neckog Industries’ proprietary mold release presents a new era in the production of foam parts. It simplifies manufacturing processes, improves quality, and reduces costs. As Neckog Industries leads the way, manufacturers can expect a future where the production of foam parts is more efficient and cost-effective than ever before. The unmatched precision and versatility of Flovv-e, combined with the proprietary mold release, promise to be a catalyst for innovation and success in the manufacturing landscape, reshaping the way foam parts are crafted.